Manufacturing Capabilities

Read this for a crash-course on Design-for-Manufacturability with CogChamp's machines.

Backside Considerations

Our machine doesn't have a sub-spindle, so it can't do backside operations. The "back" surface of the part must be flat (it can have a through-hole). And to automate as much as possible, the chuck only holds onto a "handle" of additional stock - never the part itself.

When your part gets cut off from the stock, there is usually a small "nub" on non-through-hole parts or a "annular ring" on through-hole parts. We'll clean these up by hand or manual lathe if possible. If you'd like us to do something different, make sure to tell us when you place your order.

Choosing the Backside

The "back" of the part (the side that points toward the chuck) is automatically chosen by our software based on the following rules:

- If the part has an inner bore, the largest bore diameter faces away from the chuck.

- (If above is not definitive) if the wall thickness (outer radius - inner radius) is less than 0.040 inches on one side, that side faces away from the chuck.

- (If above is not definitive) The orientation that would result in the lowest ratio of Length:Diameter at any point along the profile is selected.

- (If above is not definitive) the side with the smallest surface area (still greater than 0.025 square inches) faces away from the chuck.

Tool Radii

We did our best to choose tools that give the best balance between durability and lowest tool radius, so you can get sharp corners in your parts. As a general rule of thumb, expect tool radii of up to 0.006 inches for internal bores, and up to 0.016 inches for external turned features. This does not affect gear surfaces.

Live Center / Center Drills

If your part has small diameters compared to its overall length, it will likely need a Live Center - an additional point of support for the "free" end of the part that faces away from the chuck.

For parts with an internal bore, the Live Center can seat itself in the bore.

For parts with no internal bore, we have to drill a tiny "center drill" for the Live Center to fit into. These are pretty common - once you know what they are, you'll see them on everything.

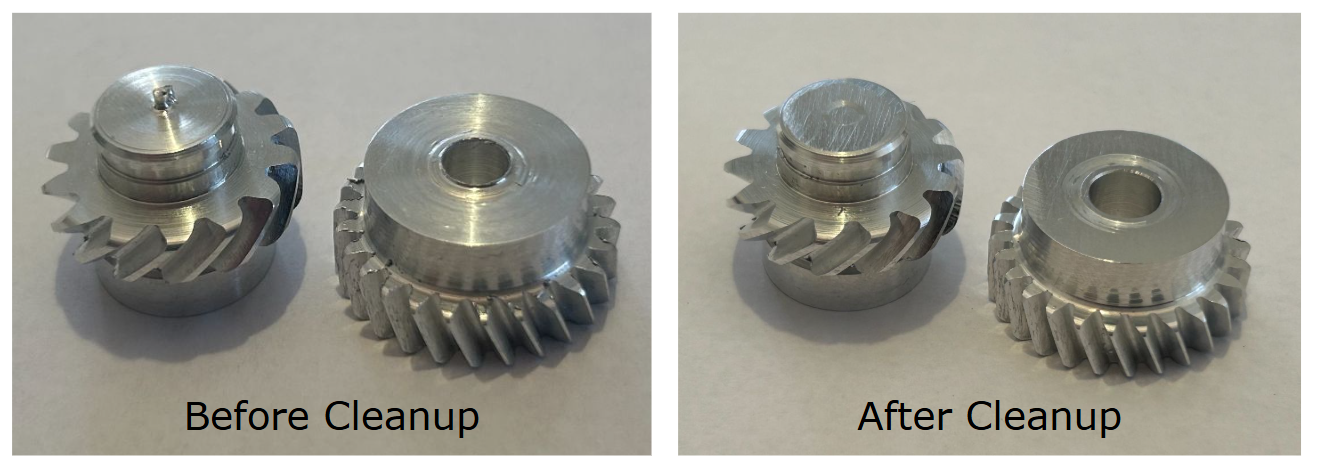

Deburring

Burrs happen on most machining operations, but they can be especially pesky for gears. We give every gear a deburring with a high-speed brushing tool after machining.

How our Lathe Works

There's lots of CNC lathes out there that do some pretty cool stuff, but we wanted something a little different. We needed a lathe that would turn a part, cut gears into it, and then part it off - all in one setup.

Oh, and it had to run off of a dryer outlet in a garage. That didn't leave many commercial options. So we built our own! Its name is Bugs.