How We Work

Curious about how we turn your designs into reality with just a few clicks?

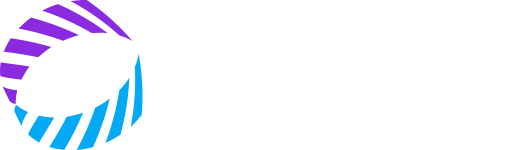

Profile Generation

Every part starts with a revolved profile. This is the shape of your part before we cut away any gear teeth, threads, etc. When you upload your design, create it with X-Y points, or use a template, our server analyzes your profile to check that it is manufacturable. It also quickly creates a machining strategy so we can give you an accurate cost when you pick your material.

Material Selection

You pick your material and we instantly check if we have enough in stock.

Added Features

Add features like gears, holes, and threads. The price and lead time are instantly re-calculated so you know exactly how much your part will cost. As you add more features, our servers check for common (and uncommon) design flaws or manufacturability errors, then give you warnings or suggestions for adjustment.

Order it

Once you click order, your parts go into our automated manufacturing queue. Right before your part gets machined, our Computer-Aided-Manufacturing (CAM) tool instantly checks all the available tools in the machine, strategizes the optimal way to make your part, and generates the G-code for your part in under a second.

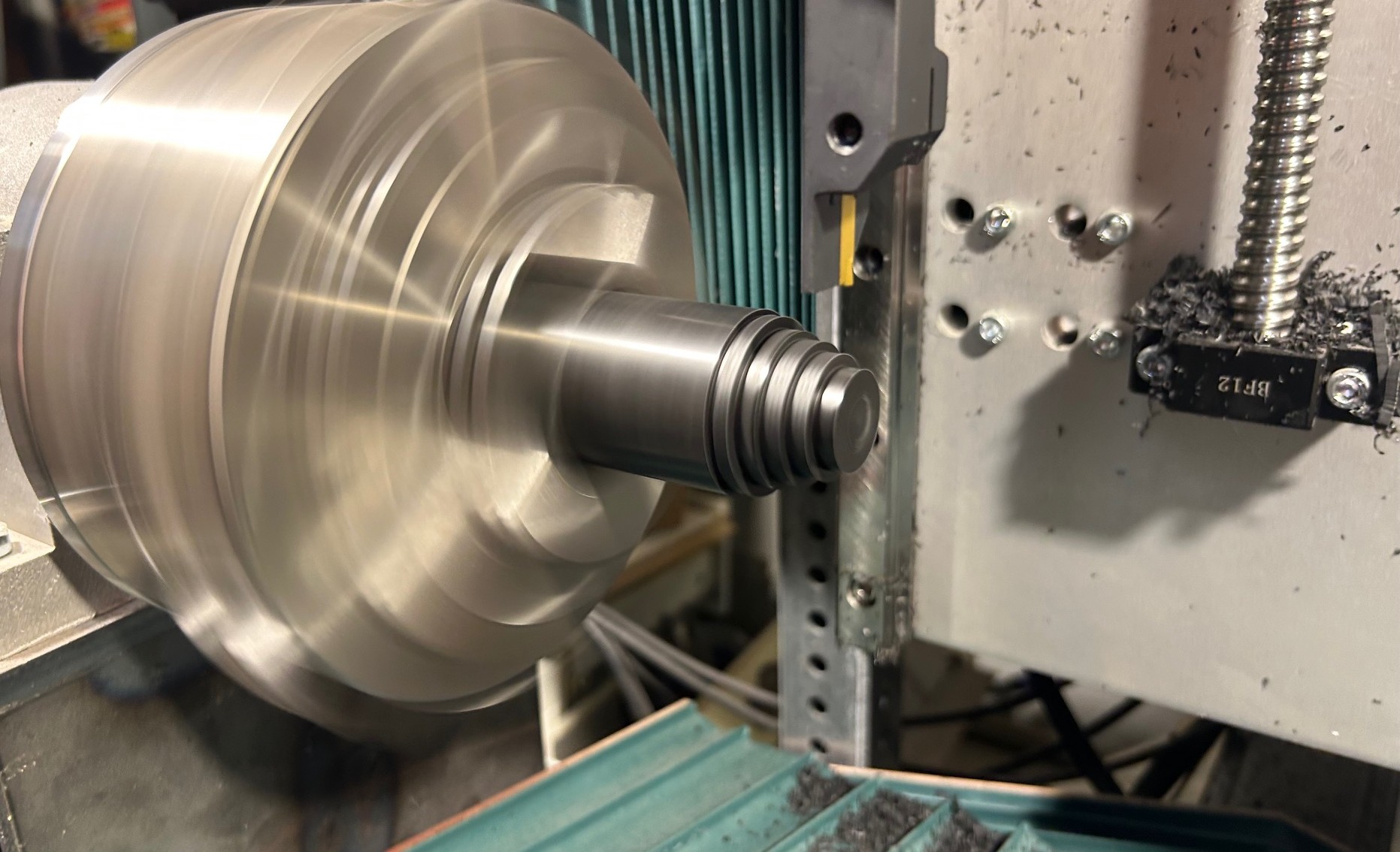

Manufacturing

The G-code gets loaded into the machine and it starts making your part. Most of the time, the process includes facing, inner diameter boring & finishing, outer diameter roughing & finishing, gear cutting, and then parting. Speeds and feeds are automatically optimized for the chosen material.

Inspection

We check a few inner diameters, outer diameters, and gear/thread dimensions over pins, even if you don't ask us to. Not only does this make sure your parts are in-spec, but it helps us know that our machines and tools aren't drifting. If anything doesn't pass, we remake it at no extra charge.

Packaging and Shipping

Once your parts are done, we bubble-wrap each part individually and send them off to you.